THE IMPORTANCE OF DISPENSING THE RIGHT AMOUNT – ISSUE NO. 467

May 1, 2018

The other day I was having one of my favorite foods in Metro Detroit, the coney dog. I was at Lafayette Coney Island, which, in my opinion, has the best coney dog around. Anyone who knows me knows I love Detroit, and this is one of those iconic places you must visit. Anyways, I ordered my usual two coneys, heavy everything (onions, mustard and chili). Well, when I got my hot dog, it was not as "heavy" as I've had before, but still heavy compared to a "regular" coney dog. This got me thinking; it depends who is making the coney dog. It's not always the same because what is heavy for one cook, might not be heavy for another. It's subjective. So what does this have to do with us in the medical device reprocessing profession? A lot.

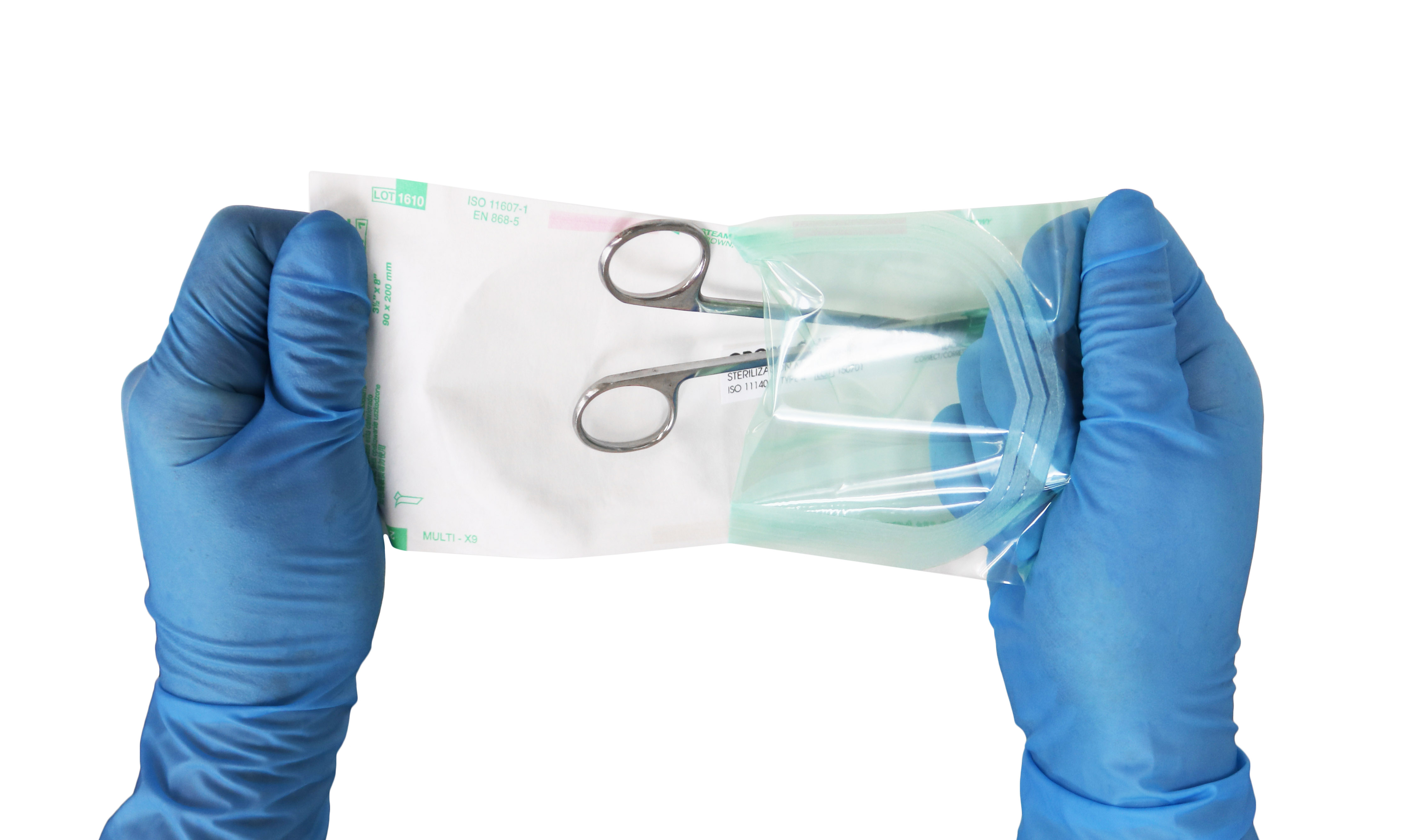

This past week we posted many great articles. One focused on the role dispensers, proportioners and injectors play in our workplace. This is a great quote from the article, "provide reliability and accuracy for mixing and delivering." My answer to getting a consistent coney dog with heavy everything would be to "automate the process." The article focused on the importance of accurate dosing. In our field, think about how we have changed from the "glug, glug" method of dispensing solutions, to more accurate options. We can't just trust these methods are working, we must also verify they are working. I started thinking back to when I first starting testing washers in 1999, and the issues I had. One of the major ones was cleaning solution accuracy. Some of the most vital cleaning equipment in our department depends on accurate dispensing of cleaning solutions. Back in 1999, I started using the T.O.S.I. when nobody wanted to test washers, or they relied on testing by the installer and nothing more. Man did I learn quickly about medical washer issues and the effects those issues had on not getting medical devices clean. Using a test was unheard of back then, and that is still the case at times today. Even with a test as simple to use, and easy to interpret as the T.O.S.I. on the market. That's why I started using the T.O.S.I. and continue to advise people to use it today. It can help you resolve issues that arise from inaccurate dispensing of cleaning solutions, impingement issues, etc. As the saying goes, "you have tried the rest, now use the best."

Yes, I actually thought of this article as I ate my coney dog. The variance in dispensing my condiments related to what I have, and continue to see, every day in our profession when it comes to dispensing cleaning solutions. There's a lot of variance and trusting it is working rather than testing the equipment with proven products. Now back to my coney dog...with that I don't mind the variance that comes with each cook. With my cleaning solutions however, I want a process that is accurate and consistent each and every time. I also want to ensure that is happening using the best cleaning indicator test possible, and it is the T.O.S.I. How else are you going to ensure that you are keeping it clean?

HAVE A QUESTION?

WE ARE HERE TO HELP

Have a question about our products? Contact us today to speak directly to a Healthmark team member or shop our catalog now to request a inquiry