PREPARING TO RESTART ACTIVITIES – ISSUE NO. 569

May 1, 2020

Spring affords us the opportunity to bring out our summer toys and for many of us, those toys range from the riding lawn mower to campers, motorcycles, quads, jet skis or other powered watercraft. Care was taken when it was put away for the winter (for those of us up North) and now when we bring it out of storage, there are steps that need to occur to prepare for their use. In my case, I store a small open bow boat underground in a mine throughout the winter months. With summer just around the corner, when I am permitted to retrieve it and bring it back out to the light of day (hopefully soon), I will have to dust it off and get the engine ready for a season of use. I start with new oil and filter, replace the fuel filter/water separator and install and charge the battery. The outdrive fluid needs checked, and the propeller needs greased and put back on. Lastly, fresh fuel is put in the tank before firing it up for the first time in months. I start it in the driveway to make sure everything is in good working order before I take the family onto the open water and must rely on it functioning at its best. I also take the time now to refresh myself on navigation rules and review the controls and operation of the vessel.

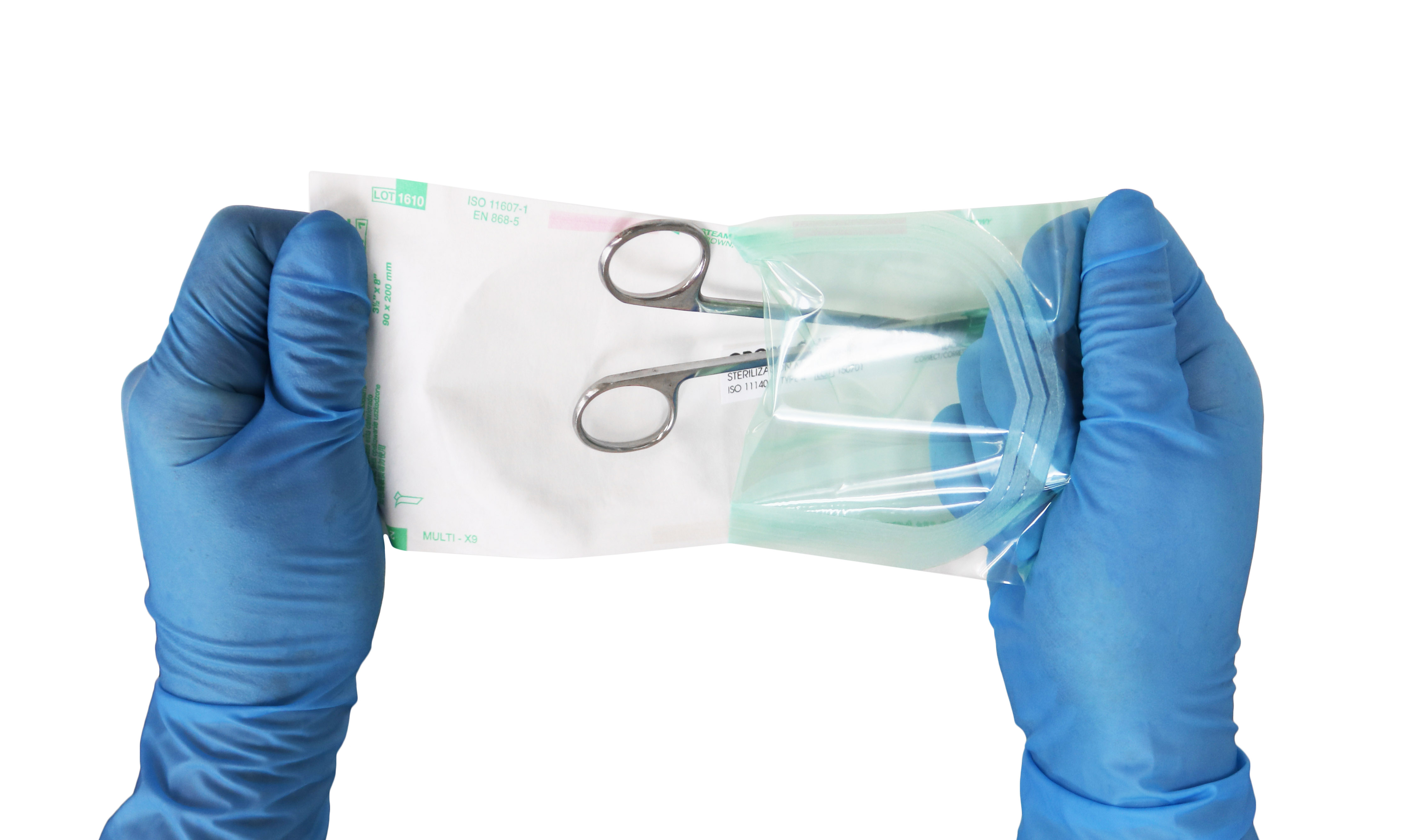

Similar activity is about to begin in healthcare. With the pandemic, elective surgeries and endoscopic procedures have been postponed and only the most critical surgeries are being performed. Sonics, washers, sterilizers and AER’s have sat idle for over a month or longer. This vital equipment typically runs 24/7 or at least M-F for 8 hours a day. Before the start of elective surgeries and endo procedures, this critical equipment should be prepared to be placed back into service. Water in the lines connecting to the washers and sonics should be flushed, detergent lines purged, and detergent efficacy be evaluated if containers were left un-sealed during this time. Equipment requalification should occur. For qualification testing, Sterilizers use Biologicals (the greatest challenge to the process) and washers the TOSI® test (a surrogate device to a soiled complex instrument) as both products are the gold standard to verify performance. For Ultrasonic cleaners, cavitation should be tested using a SonoCheck™ and cleaning ability verified with a TOSI® and a Lumcheck™ if the ultrasonic has a pulse flow or irrigation cleaning ability.

When you get the heads up that surgeries are about to get going again, give us a call. We can help with performing virtual staff in-servicing and cleaning verification best practices. We appreciate all the hard work and dedication of our front-line Healthcare workers and the manufacturers that have worked tirelessly to help ensure our towns and communities are safe and can provide the best care possible. THANK YOU ALL!

HAVE A QUESTION?

WE ARE HERE TO HELP

Have a question about our products? Contact us today to speak directly to a Healthmark team member or shop our catalog now to request a inquiry