SUSTAINABILITY IS THE LATEST BUZZ WORD! – ISSUE NO. 76

November 1, 2010

Last week I wrote about our trip to Finland. Here is the rest of the story.

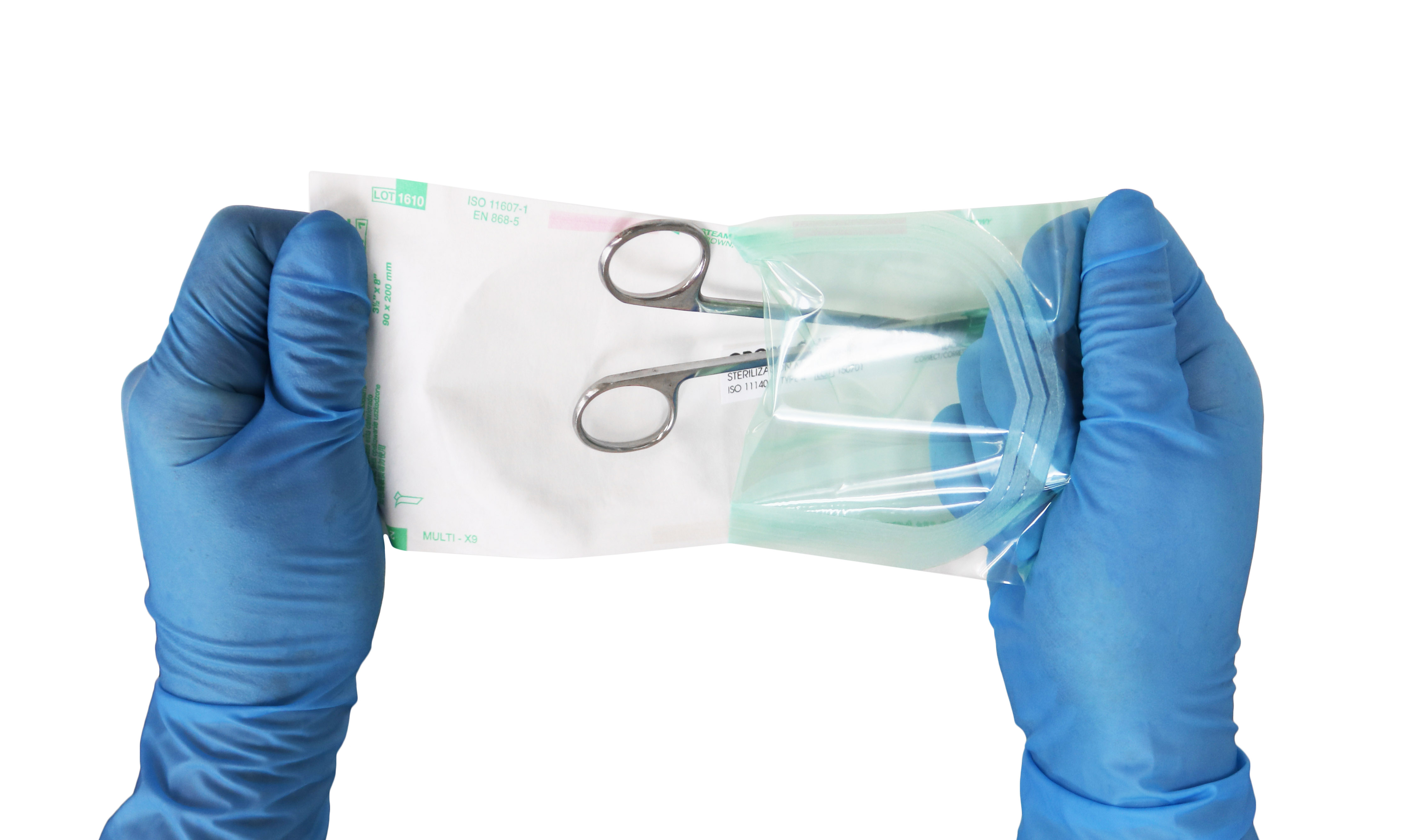

Our last stop of our first day in Finland was the largest CSSD in the city. This was one busy place, serving 8 hospitals, delivering 70,000 plus items per month. They use state of the art robotics, and much more. We were struck by the types of items that are considered reusable. There's no doubt these product were receiving a thorough cleaning and not adding to the waste stream. What was particularly interesting was the very small use of sterile wrap. Most items are either placed in container systems or in a pouch.

Our second day in Finland began with a visit to Wipak's Medical Nastola facility (FYI, they have 12 plants in the US & Canada) completing our required bi-annual audit. Our check list included environmental/sustainability plans. There are plans and then there is action. Wipak believes action. The most impressive example was their furnace (remember Scandinavia - cold). They recover ink fumes and burn them for heat. Other examples include the pouch machine scrapes which are recovered right-in-line and re-used in a variety of ways. As for making pouches, you can rest assure the three story film making machines, team of engineers, quality and lab folks are the best in the world. Unlike many other pouch companies, Wipak starts with the plastic granules that results in a final product that must pass multiple quality steps so you can be confident it will work in the OR.

HAVE A QUESTION?

WE ARE HERE TO HELP

Have a question about our products? Contact us today to speak directly to a Healthmark team member or shop our catalog now to request a inquiry