VALIDATION AND VERIFICATION – ISSUE NO. 21

October 1, 2009

It's AAMI document review and preparation time again. The Association for the Advancement of Medical Instrumentation (AAMI) is the group that is recognized for setting the voluntary standards for all healthcare facilities and medical device manufactures, when it comes to "best practices" in surgical instrument reprocessing. One of the symbiotic definitions that comes up often in these documents are validation versus verification.

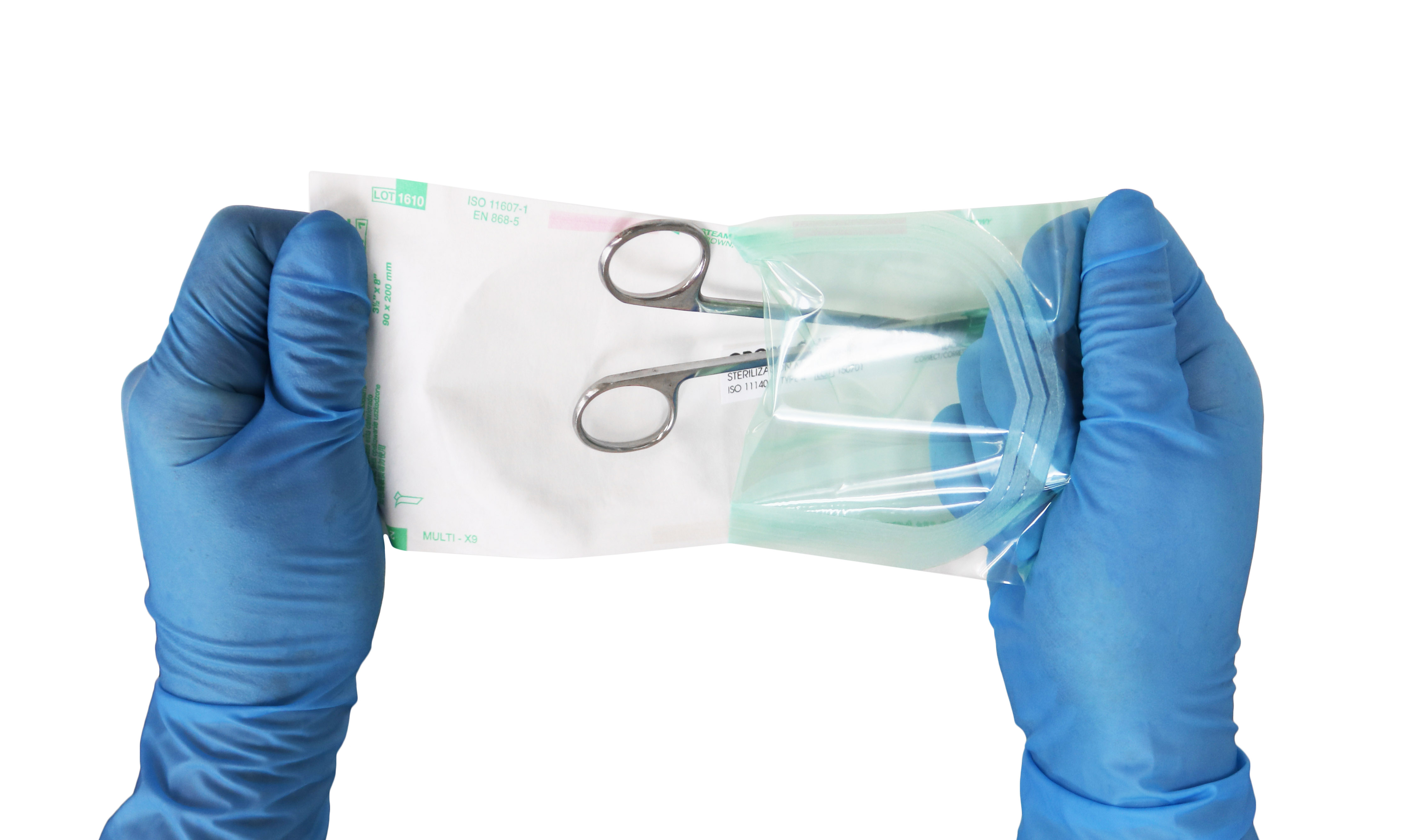

Most simply stated, healthcare facilities (the users of medical devices) verify that they are complying with the validated instructions provided by the medical device manufacturer (MDM). The FDA places the burden upon the MDM to document that the methods they recommend to the user of a device have undergone rigorous scientific testing to demonstrate that the method (i.e., sterilization) will achieve the expected result in a healthcare facility.

The user of the device, needs to verify that they are 1) following the instructions provided by the MDM and 2) are achieving the expected results (i.e., instruments exposed to sterilization conditions). Having said this, sometimes healthcare facilities need to do more - they need to validate a process. This occurs when, for example, a facility plays the role of the MDM - for instance designing a unique set of instruments in a container, or utilizing a device in a way not described by a MDM in their validated instructions.

Validation and Verification, 2 very important sides of the same coin - making sure things are done right.

HAVE A QUESTION?

WE ARE HERE TO HELP

Have a question about our products? Contact us today to speak directly to a Healthmark team member or shop our catalog now to request a inquiry